Pre-Sales

At NEWNTIDE, we understand that every business has unique needs and goals. That’s why we offer a range of services designed to help you succeed in your market.

1. OEM Service

Our OEM service helps clients expand their product lines under their brands. We leverage our manufacturing expertise and efficient manufacturing processes for faster market entry.

2. Co-brand or NEWNTIDE Brand

Co-branding with “NEWNTIDE” enables you to use our strong reputation while keeping your brand identity. As a dealer, you have access to a full range of NEWNTIDE-branded products to boost credibility, consumer trust, and sales growth.

3. ODM Service

We offer complete ODM support, from concept to mass production. Our product development expertise and advanced tech will create innovative solutions that improve your edge.

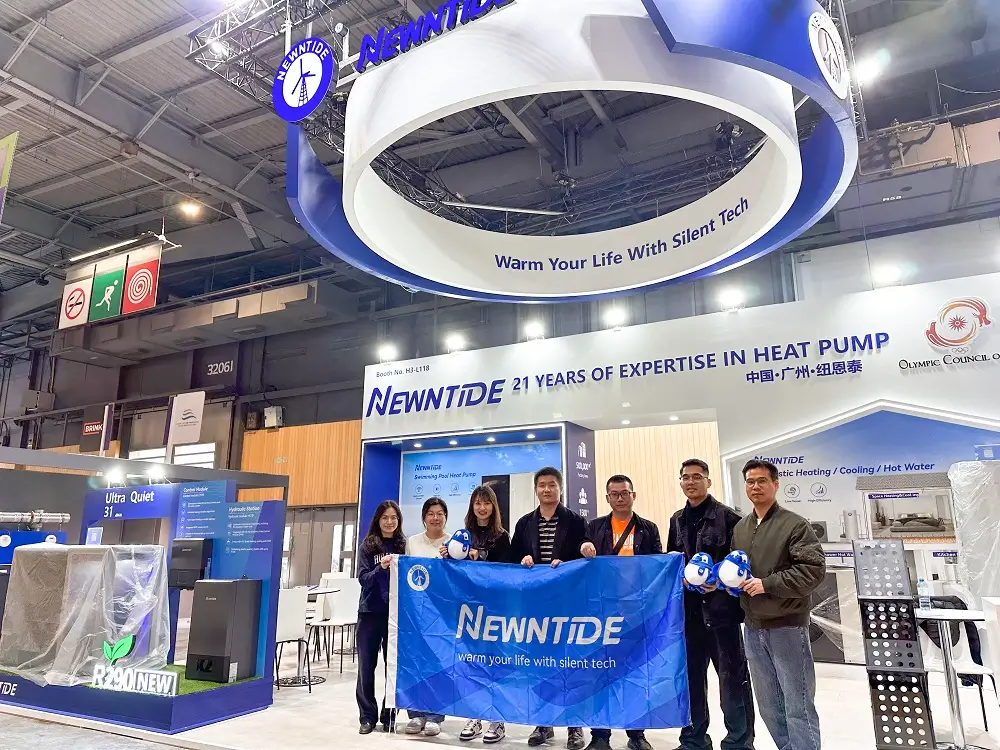

Attend Expos

To stay updated on industry trends and connect with partners, NEWNTIDE regularly attends international expos. These events allow us to showcase our latest heat pump innovations and solutions.

Interclima 2024, French

MCE 2024, Italy

Canton Fair 2023, China

ISH 2023, Germany

Piscina Barcelona 2023, Spain

ISH China & CIHE Beijing 2024

MCE 2022, Italy

HPE Expo 2024, China

In Sales

Model Selection

With over 20 years of experience and a professional team of more than 1,500 experts, we are committed to helping you select the most suitable products and solutions that align with your specific needs and local market demands. Our team goes beyond providing product recommendations, offering creative and flexible project design suggestions tailored to your goals.

Certificates Application

NEWNTIDE offers comprehensive support in securing the essential certifications required for your business, tailored to meet the specific regulatory standards of different countries. Whether you are entering new markets or maintaining compliance in existing ones, we empower your business to operate confidently on a global scale and drive success across borders.

Get a Quote

After-Sales

Customer Visit

Our commitment to your satisfaction doesn’t end with the sale. Our experienced engineers visit customers frequently to provide support in the local market. During these visits, we provide valuable after-sales updates, hands-on technical training, and comprehensive installation guidance.

Warranty Service

We offer a fixed warranty for heat pumps and the components and are committed to delivering maintenance, prompt repairs, and the replacement of spare components as needed. Our team is always ready to ensure your product continues to perform optimally, maximizing the value of your investment.

Technical Training

We offer professional technical training and consultation both online and on-site, covering everything from installation and troubleshooting to problem-solving and user instruction. By equipping you with essential expertise, we ensure that you can fully utilize and maintain your products in the long term.

FAQ

An air-to-water heat pump is an efficient heating and cooling system that extracts heat from the outside air and transfers it to water, which can then be used to heat or cool indoor spaces or supply hot water. The operation of an AWHP is based on thermodynamic principles, and utilizes a refrigeration cycle to achieve this energy transfer efficiently.

Heat pumps are highly efficient, cost-effective, and eco-friendly. They provide both heating and cooling, use renewable energy sources, and have lower carbon emissions. Additionally, they offer consistent comfort, long lifespan, and reduced operating costs.

Unlike traditional systems that burn fuel, heat pumps use electricity to move heat rather than generate it. This fundamental difference allows them to achieve extraordinary efficiency of 300–400%, meaning they can produce three to four times more heat energy than the electricity they consumed.

The noise level of air source heat pump can vary based on the model and installation location. NEWNTIDE can offer the quietest models that achieves whisper-quiet operation down to 31dB(A) at 1 meter, which is equal to the sound of whisper.

Yes, air source heat pumps are designed to operate efficiently even when outside temperatures drop below freezing. The operating ambient temperature range of NEWNTIDE’s heat pump is -28~43℃, ensuring efficient and reliable operation even under low temperatures.

Our heat pumps are versatile and designed to meet a wide range of residential needs, such as residential space heating and cooling, domestic hot water supply, temperature-controlled swimming pools. We also offer commercial heat pumps tailored to meet the demands of larger spaces and more complex applications.

Installation requires adequate outdoor space for airflow, a solid foundation for the unit, proper electrical connections, and compatibility with the home’s heating system. Professional installation is recommended for efficiency and safety.

Sure, download the “Eco-Home” app from the App Store or Google Play, and follow the simple on-screen instructions to connect your smartphone to your heat pump seamlessly.

The compressor, as the heart of your heat pump, is covered by an extended 5-year warranty, and all other parts of the heat pump are covered under a 2-year warranty.

Yes, we provide customization options to meet specific customer needs. Whether it’s tailored specifications, unique designs, or advanced features, our team works closely with you to deliver heat pump solutions that align with your requirements. Contact us to discuss your customization needs!

.webp)